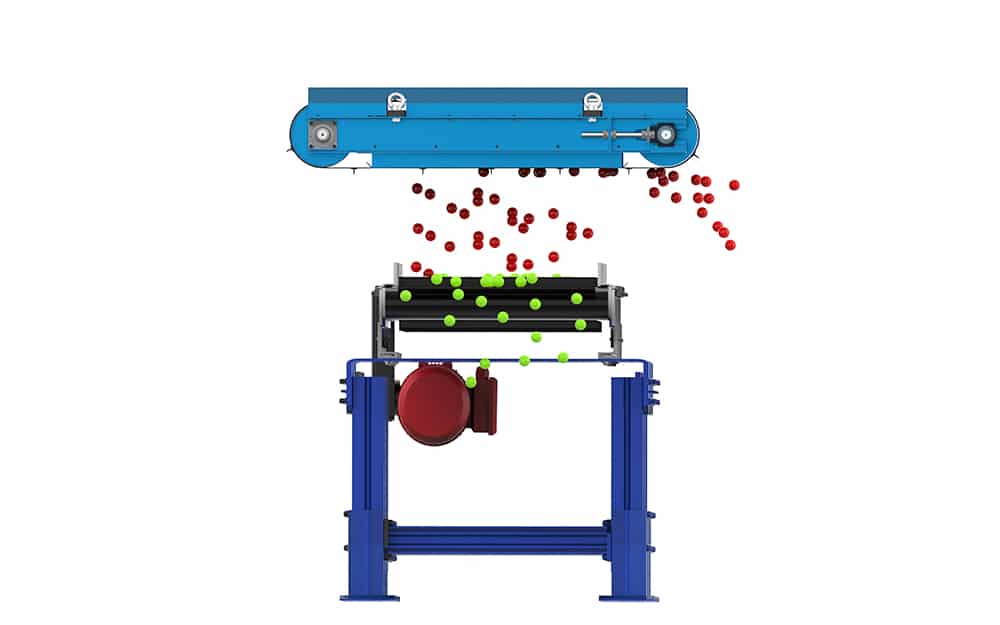

Positioned perpendicular to the conveyor belt

This kind of magnets are positioned perpendicular to conveyor belts and are used to remove ferrous materials from the material stream as it passes beneath. By creating a strong magnetic field across the conveyor, these magnets attract and lift metal particles away from the rest of the material flow, ensuring efficient separation. After moving through the magnetic field, the metal particles are released into a designated receptacle. Cross overbelt magnets are commonly used in industries like recycling, mining, and waste processing to protect downstream equipment and improve product purity.

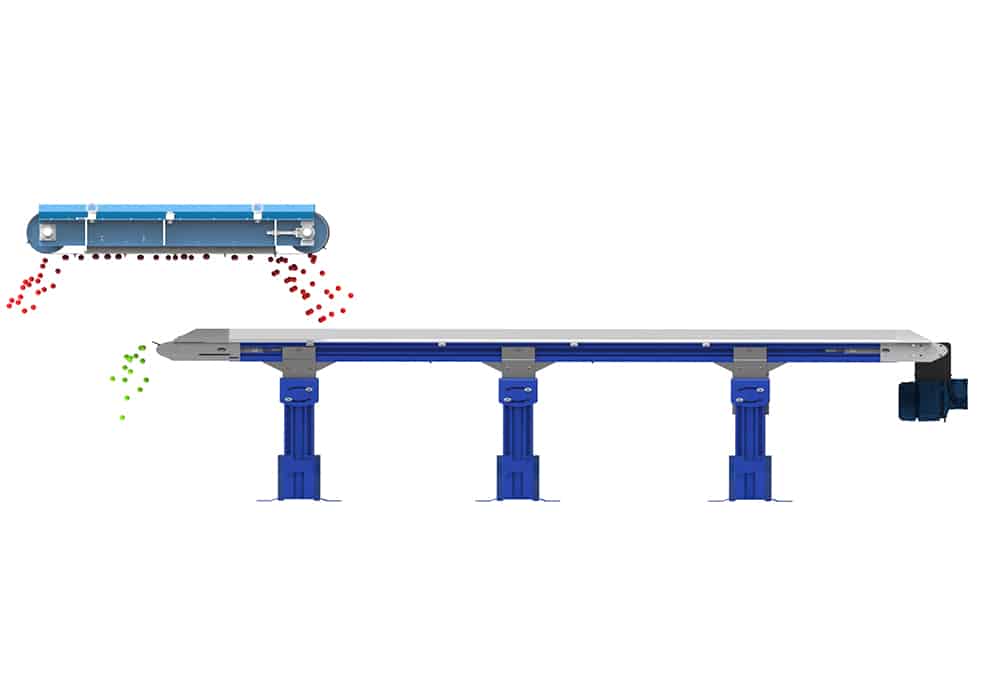

LENGTH OVERBELT MAGNETS

Positioned parallel to the conveyor belt

Length overbelt magnets are positioned in line with the direction of a conveyor belt, extending the time ferrous materials are exposed to the magnetic field. This setup allows the magnet system to more effectively remove ferrous particles from the material flow, as the particles remain within the magnetic field for a longer duration, improving separation efficiency. The multipole transport magnet “cleans” the attracted ferrous particles by spinning them within the magnetic field, causing non-magnetic particles to fall off. The overbelt’s speed is set to match or exceed the speed of the conveyor belt beneath, ensuring that longer ferrous particles are transported away without damaging the conveyor.

NEODYMIUM OVERBELT MAGNETS

Extra strong Neodymium version

The extra-strong Neodymium overbelt magnets are designed for applications requiring powerful separation of even the smallest ferrous particles. These magnets use Neodymium, a rare-earth material known for its exceptional magnetic strength, which makes them much stronger than standard ferrite magnets. This increased power enables the magnet to capture fine or weakly magnetic particles that might otherwise pass through. Ideal for demanding industries like recycling, mining, and metal processing, Neodymium overbelt magnets provide highly efficient metal separation, improving product purity and protecting downstream equipment from potential damage.