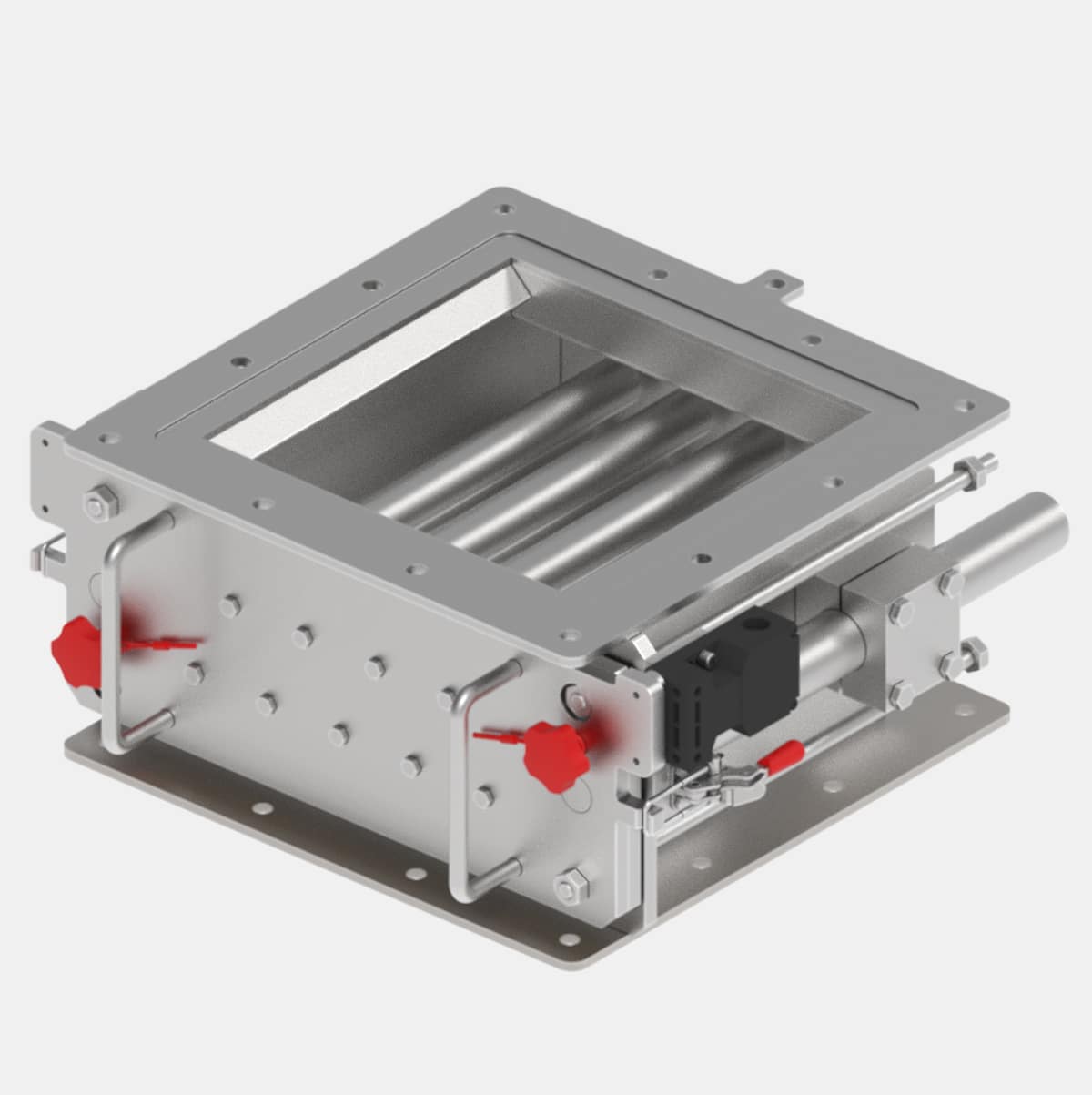

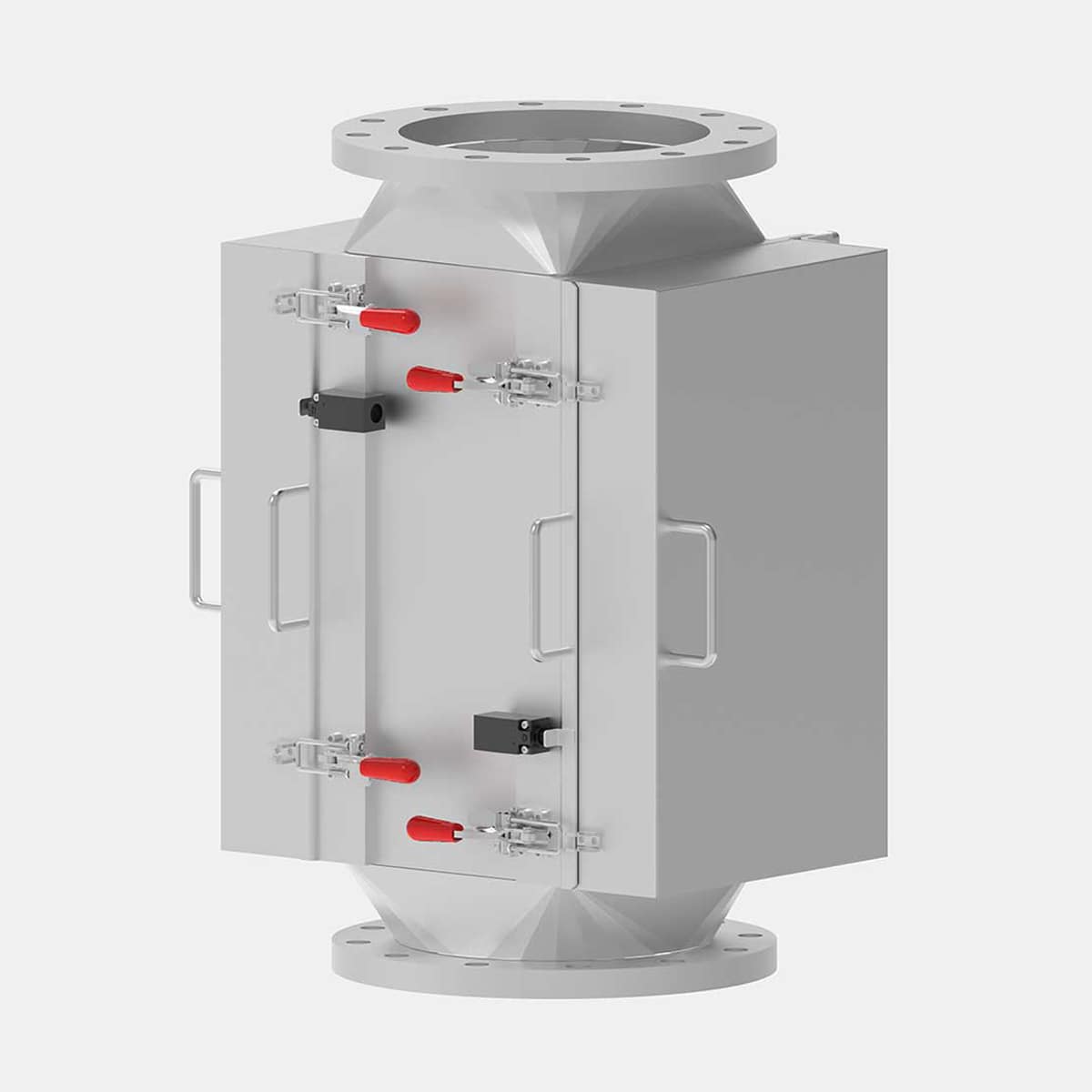

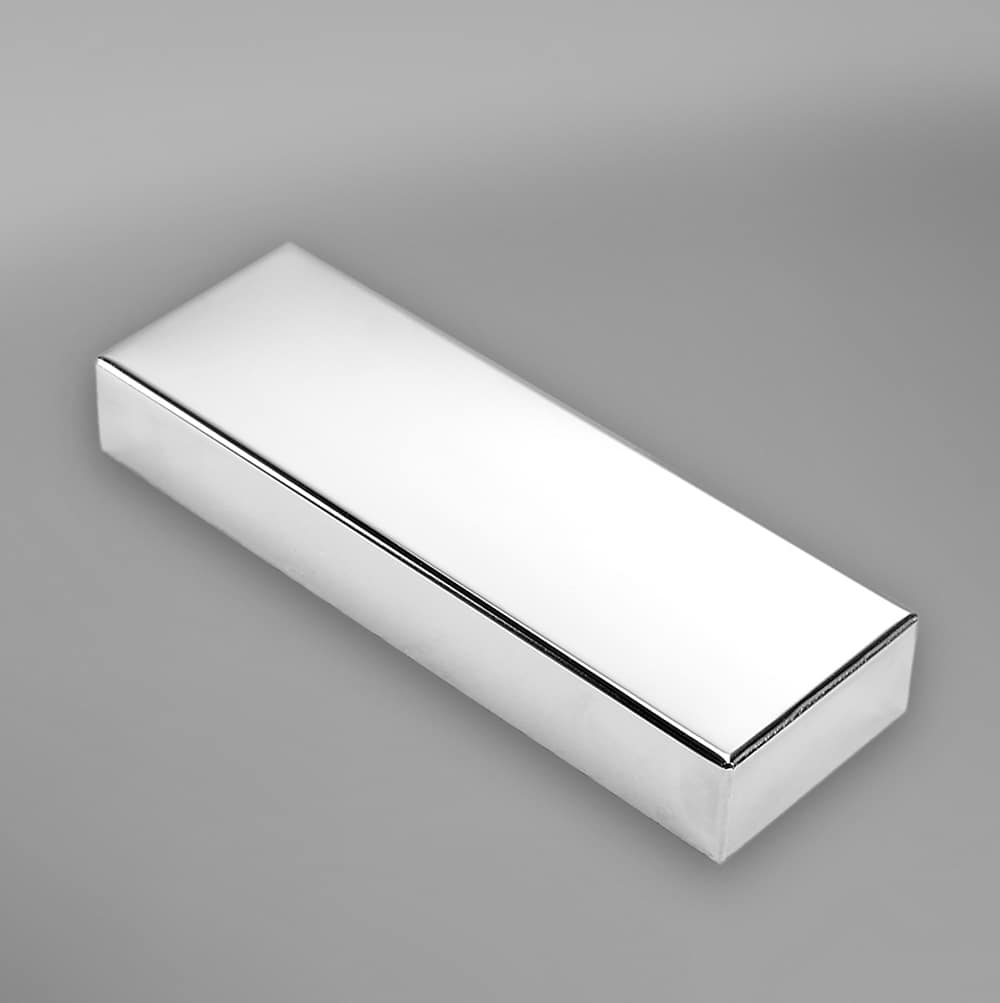

By using high-strength magnets, this process effectively removes ferrous contaminants from oil, gas, and chemical streams, protecting sensitive machinery from damage and significantly reducing maintenance costs. It also safeguards catalysts in refining processes, ensuring uninterrupted operations and maximizing their effectiveness in converting raw materials into valuable products.

These solutions play a crucial role in meeting stringent industry standards by minimizing the risk of contamination, which can compromise product quality and disrupt production processes. The enhanced protection and efficiency provided by magnetic separation contribute to the reliable production of industrial products, supporting the industry’s focus on operational excellence and high-quality outputs.

Our industrial products meet all the heavy demands of this kind of industry.

Furthermore, magnetic separation improves workplace safety by reducing the likelihood of equipment malfunctions caused by metallic debris. It also promotes sustainability by preventing waste, extending the lifespan of equipment, and optimizing resource utilization. By integrating advanced magnetic separation technology, petrochemical companies can achieve improved operational performance, lower environmental impact, and greater competitiveness in global markets.