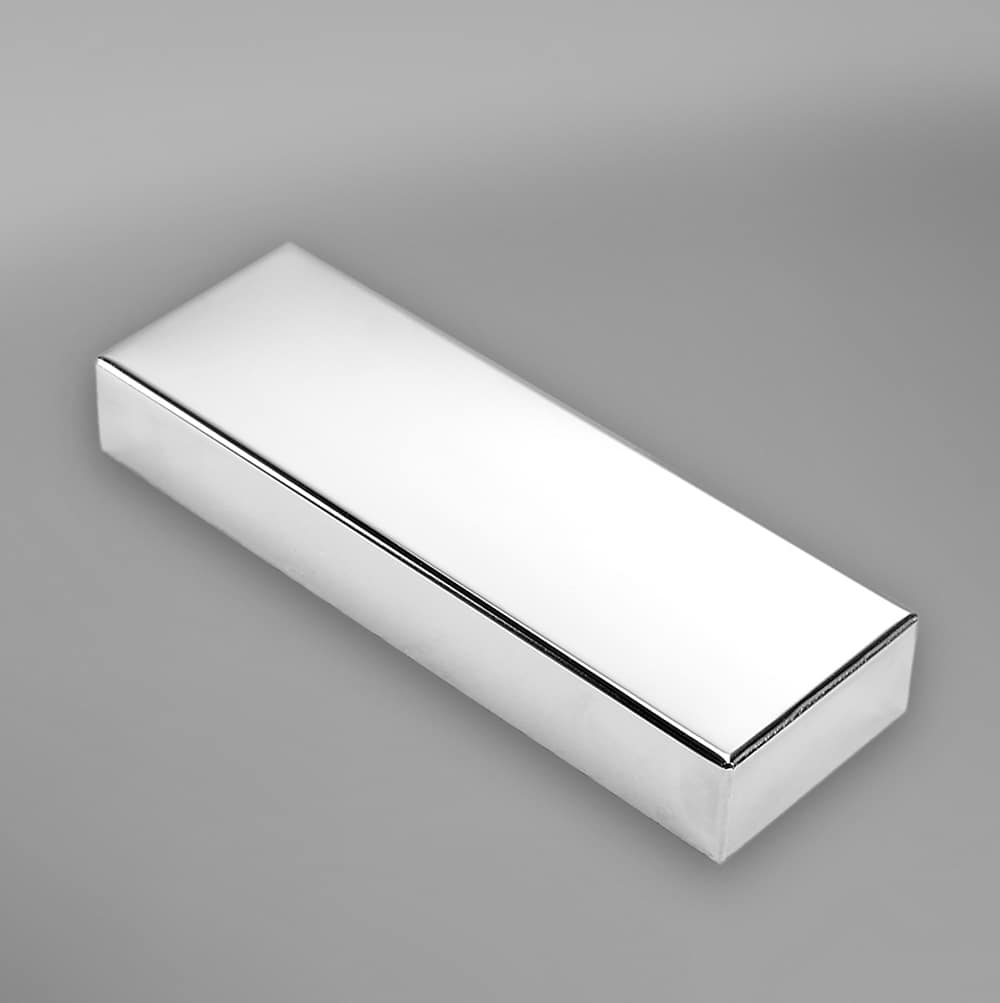

Magnetic separation is a cornerstone of food production, playing a vital role in ensuring product safety and quality by effectively removing metal contaminants from food processing lines. High-intensity magnets are strategically placed to capture ferrous particles, protecting machinery from potential damage and preventing harmful metal fragments from entering the final product. This safeguards not only production equipment but also the integrity of food-grade products, ensuring they meet the highest standards of safety and quality.

The process is instrumental in helping manufacturers comply with stringent food safety regulations, such as those outlined by EHEDG standards. By eliminating contaminants, magnetic separation improves the purity of food-grade products, which is essential for building consumer trust and maintaining brand reputation. Additionally, it reduces the risk of product recalls and associated financial and reputational damage, making it an indispensable part of modern food manufacturing.

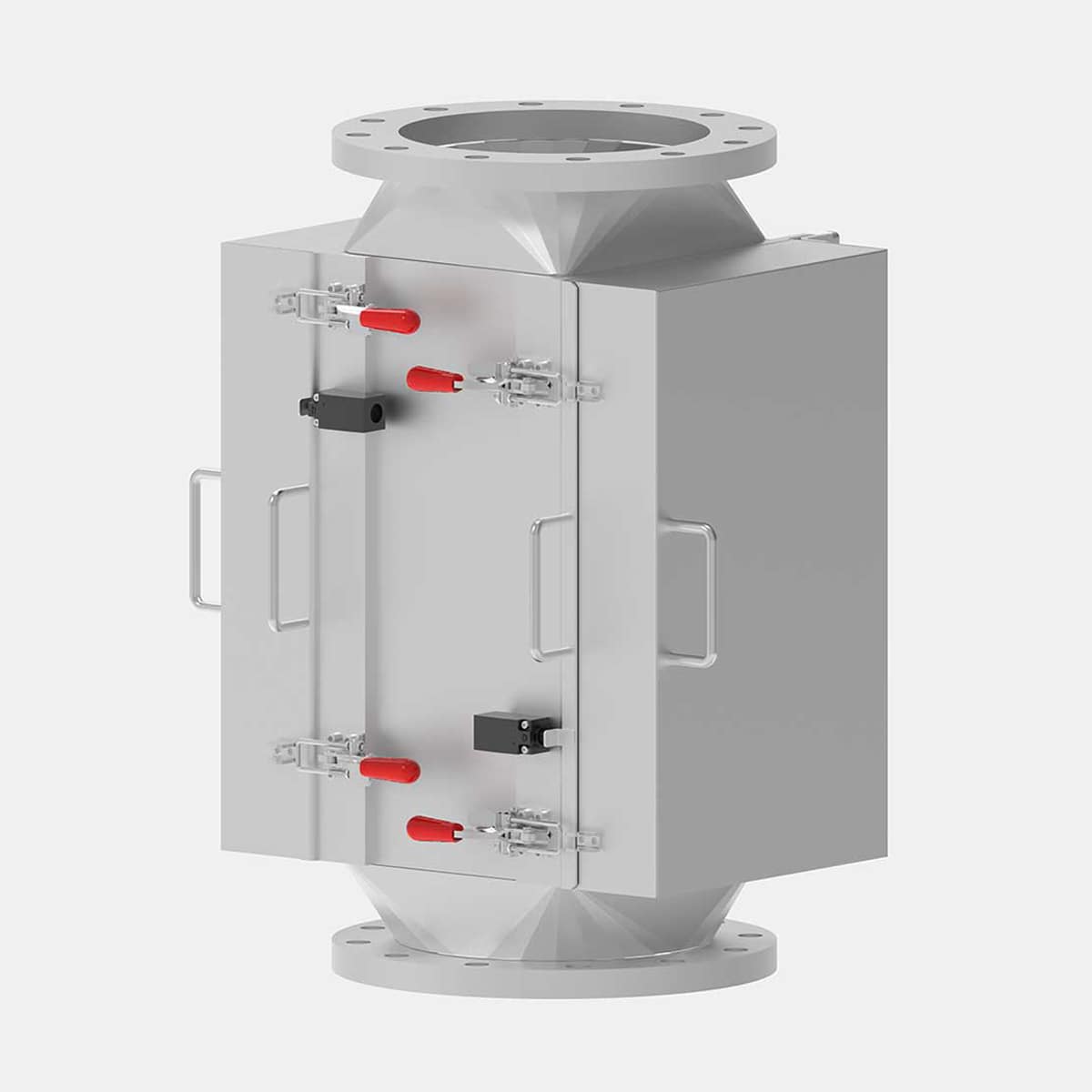

Magnetic separation technology is highly versatile, accommodating a wide range of food products, from powders and grains to liquids and pastes. It is especially critical for ensuring the safety of sensitive food-grade products, such as baby food, dairy products, and beverages, where even the smallest contamination can have serious consequences.

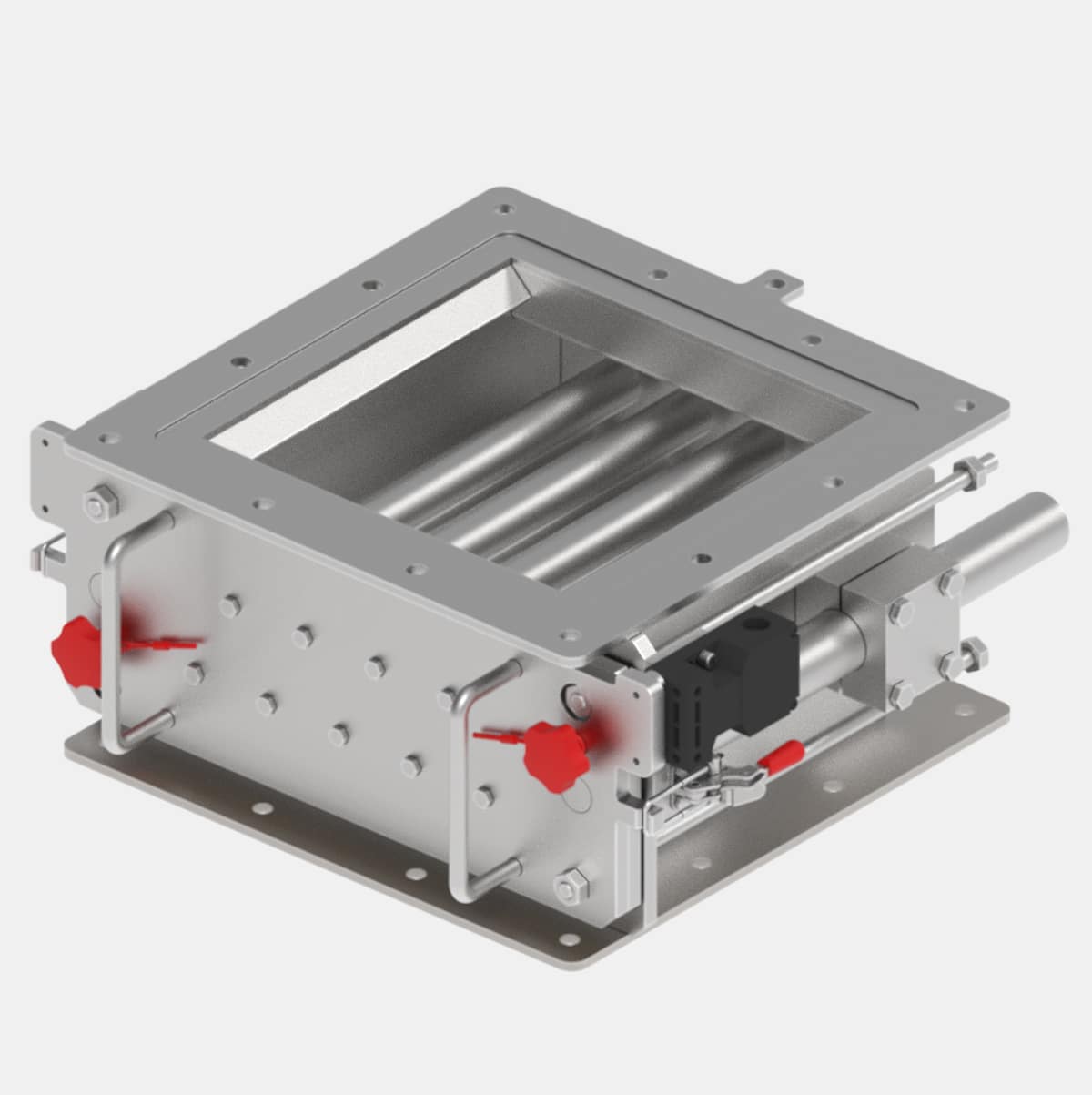

Moreover, the implementation of magnetic separation systems contributes to operational efficiency. By automating the removal of contaminants, manufacturers can maintain a continuous production flow, minimize downtime, and reduce waste. This not only enhances productivity but also supports sustainability by optimizing resource use and reducing material loss.

In summary, magnetic separation is an essential process for ensuring the safety, quality, and compliance of food-grade products. By integrating advanced magnetic solutions, food manufacturers can protect consumers, meet regulatory requirements, and deliver superior products that align with industry standards and market demands.